If someone asks you to replace a cylinder head or a timing belt, you know it will be a fairly involved process. One that, depending on the car, can take several hours, or even a day-plus to complete. However, when someone hands you a beautifully fabricated exhaust for a four-cylinder car, a 10-hour installation does not cross your mind. One downpipe: no sweat. Wrong! Lots of sweat. Lots, and lots of sweat.

Overview Of Cobb OTR Tunes

During the process of upgrading our Fiesta ST through all of Cobbs stage kits (1-3) we have been using what they refer to as off the shelf tunes (OTR). These tunes are more than just a generic performance flash, they are developed in-house on Cobbs dyno with the parts that are included in the stage kits.

“We start with a stock car, and we spend a lot of time on the dyno to find the limits of the car,” said Bergher. “We find what parts enhance the performance and maximize the bang for the buck. On the [Fiesta ST] that was intake airflow and exhaust. We optimize timing and fuel for all conditions and extend the power curve as much as possible.”

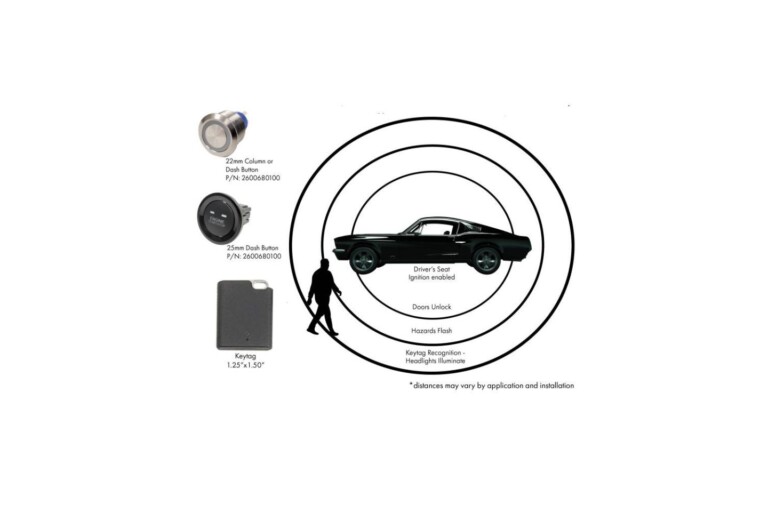

It is important to note that this is not a one-time event. Cobb continues to improve and expand its software options long after the earliest version of the tuning software has hit the market. For example, launch control and flat-foot shifting are both features that have been tacked onto the Fiesta-specific Accesport at no additional charge. Users need only download the Accessport Manager software (which is available for Apple and Windows) and update their Accessport to the latest firmware when it is available. Bergher hinted that a new version should be ready for download shortly.

As we mentioned in our install part 1, Habanero Hatch isn’t exactly the wholesome saving-herself-for-marriage girl we thought she was. After some automotive archeology revealed the car to already have had a Cobb rear engine mount and drop-in filter installed, we have more than sneaking suspicion that a full exhaust was also part of the car’s original arsenal – all of which was likely stripped off before the previous owner parted ways and sold the car.

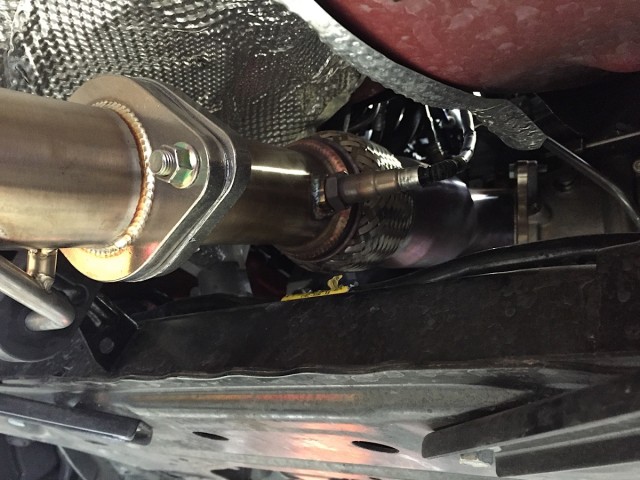

Let us be clear here: We don’t expect you to have the same experience we did. The factory bolts should not have been this hard to remove, especially considering the car only has 24,000 miles on the clock. Our hunch is that the previous owner severely over tightened them, where (due to heat) they became an unholy union with the surrounding flange material. We do, however, recommend that you allot yourself a spare day to install the kit, should you run into the problem we did. After bolt number three of the downpipe parted ways with its head, we knew we were in for a headache. When an air drill (the most compact drill we could get our hands on) was still too big to fit in the narrow confines of the engine compartment, we decided to cut our losses and pull the entire turbo/manifold assembly out of the engine. The process wasn’t nearly as difficult as expected, but did require removal of all of the coolant and oil lines, and electronic connections.

After bolt number three of the downpipe parted ways with its head, we knew we were in for a headache. When an air drill (the most compact drill we could get our hands on) was still too big to fit in the narrow confines of the engine compartment, we decided to cut our losses and pull the entire turbo/manifold assembly out of the engine. That was a process that wasn’t nearly as difficult as expected, but did require removal of all of the coolant and oil lines, and electronic connections.

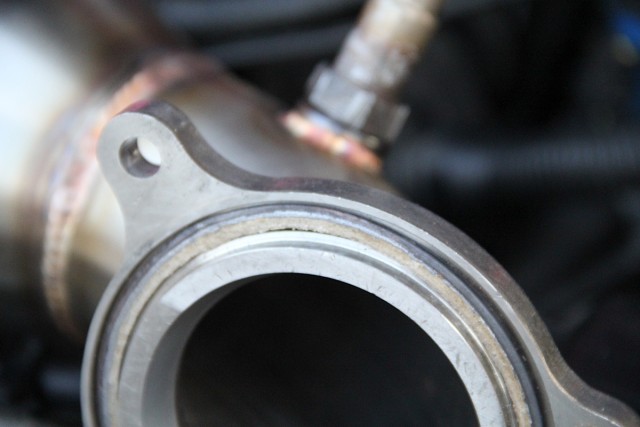

With the turbo assembly on the bench, we clamped it in the vice and drilled out all of the stubborn factory bolt stumps. Lastly, to ensure we never ran into this annoying problem again, we tapped the turbo/downpipe flange for oversize 3/8-inch bolts. From there, the install was exactly as the Cobb’s instructions promised it would be.

Installing Cobb’s Stainless Cat Back

With the turbo bolted back into the car, the remaining installation was a breeze. First up was to ditch the restrictive, original piping.

The factory exhaust needs to be cut at the rear bend in order to remove it from the car, as it is installed before the rear axle during the car’s trip down the assembly line. This chop is accomplished easily with a reciprocating saw, but a hand-powered hack saw will get the job done just the same.

Bolting the downpipe to the back of the turbo requires that the upper heat shield be removed, easily the most painful part of the process. However, with it out of the way, the three bolts can be accessed and tightened without drama.

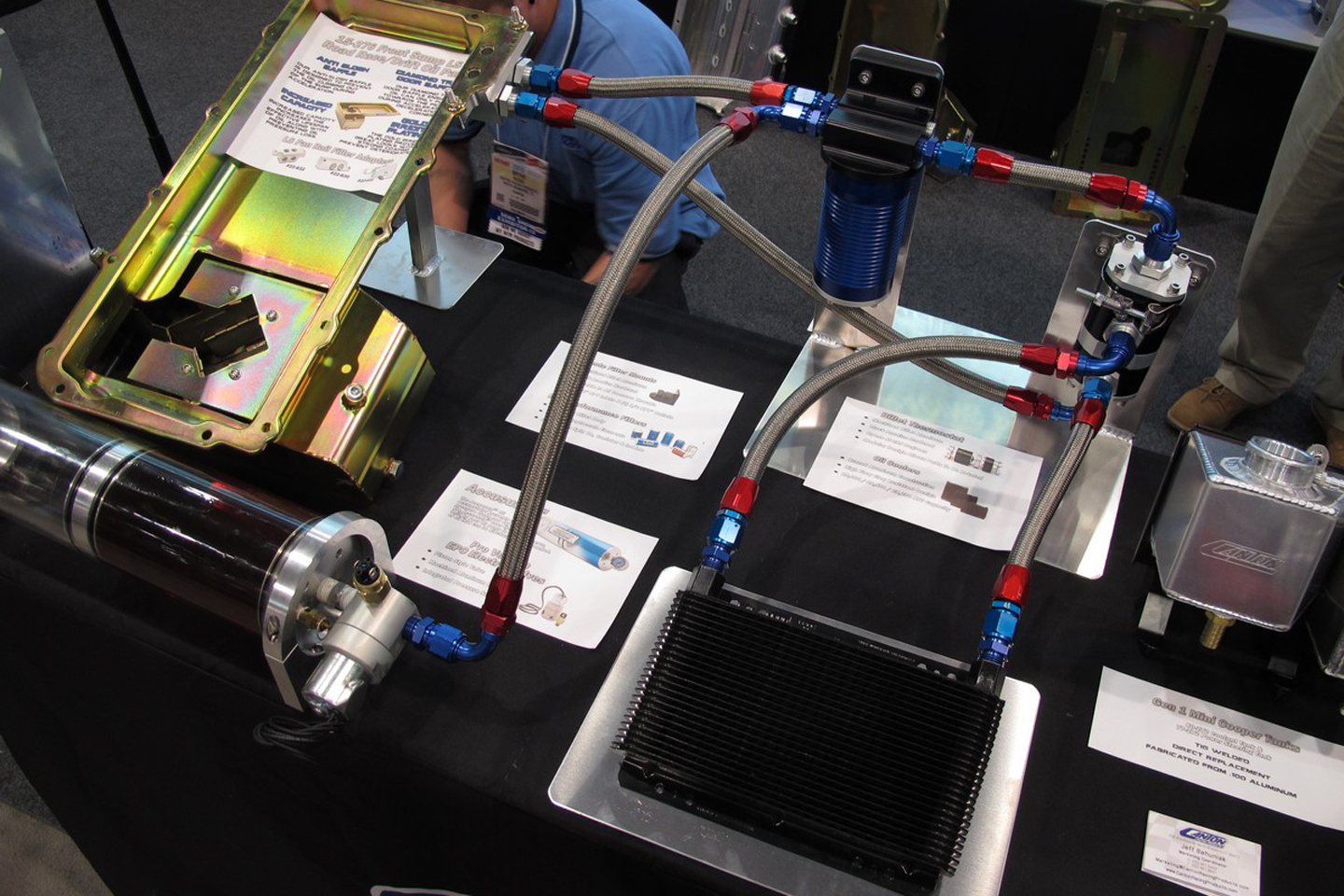

Lastly, the larger 2.5-inch, mandrel-bent stainless tubing is installed in three sections: the post-down-pipe segment, the mid-segment, and the muffler-segment. Lastly, each segment gets a new gasket and a stiffer exhaust hanger to keep them from swinging side-to-side during aggressive/competition driving.

The Sound

The Cobb stainless steel exhaust is as close to artwork as many gearheads will ever develop a cultured appreciation for. Each joint is cradled by cascading rows of flawless TIG welds, and the radius-bent piping smoothly arcs to a polished muffler and dual tips. Sadly, this gem of a system lives under-hood where few will ever get a good look at its mastery. But, who buys an exhaust for its looks? How it sounds is what you really want to know.

Is it loud? Yes. Will you be accosted by elderly neighbors chucking dentures as you drive by? Likely not. The Cobb turbo-back system fits the mold for a sport exhaust perfectly. You certainly know it’s installed when you mash the loud pedal, but on the freeway, at part throttle, we found it to actually be quieter than stock.

As previously mentioned, the welds are good, and the execution is top notch, but the system isn’t magic, nor does it add four-cylinders-worth of tone to the exhaust system. The tone is fitting of a small-displacement, inline four, but in the best possible way, and without being over-the-top or obnoxious. The exhaust pipes are 2.5 inches in diameter, a half-inch bump from the factory tubing. The extra volume is sufficient to add character and performance, but not so much that it drones or emits that hollow, ear-buckling sound we’ve all heard before. It’s a note you won’t be embarrassed to show off to friends – and the rally-esque crackle during off throttle deceleration and throttle blips is pretty badass.

Stage Three Dyno

With the full exhaust installed, we strapped Habanero Hatch onto the dyno for the fourth time to see what sort of gains were hiding in the new, unleashed breathing system.

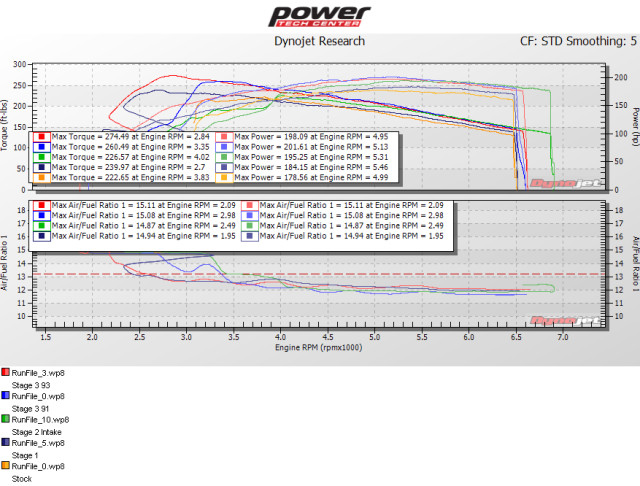

After flashing Cobb’s 91 octane, stage three tune onto the car, we let her rip. The results of the first pull rewarded us with a healthy, 260.49 lb-ft of torque and 201.61 horsepower. Keep in mind that this engine displaces just over 1 1/2 liters. This is practically stump-pulling torque! We felt like there was more horsepower in the car, and since 93 octane is not readily available in our neck of the woods, we mixed in a few gallons of VP Racing Fuel 101 octane.

Once again, we reflashed the car to suit the octane level in the tank (which mathematically was right at 95 octane) and spun the rollers for the final time. Horsepower remained virtually the same, most likely due to the fact that the car now had some heat in it, but torque picked up another 14 lb-ft. If you have access to 93 octane fuel, there is certainly an incentive to run it and the corresponding 93 octane stage three tune.

Once again, we reflashed the car to suit the octane level in the tank (which mathematically was right at 95 octane) and spun the rollers for the final time. Horsepower remained virtually the same, most likely due to the fact that the car now had some heat in it, but torque picked up another 14 lb-ft. If you have access to 93 octane fuel, there is certainly an incentive to run it and the corresponding 93 octane stage three tune.

On this dyno graph, you can see how much the car has gained from when it was stock, to stage three with the 91 and 93 octane.

At the end of the day, our car made an honest 201 horsepower and 274 lb-ft of torque. We were extremely happy with the numbers, but we had seen higher power figures elsewhere. To clarify, we got Cobb Tuning on the phone to get a better understanding of what variables could influence output.

“There is constant feedback from the knock sensors and the car has an octane adjust learn ratio built into the ECU,” said Braden Bergher of Cobb Tuning. “That can definitely affect dyno runs. Cars with stage three kits typically produce between 200-220 horsepower, a little more with an aggressive Pro Tune. The stock turbo really is the limiting factor on the car.”

Cobb has conducted extensive research on Ford’s octane adjustment system (OAR) which is available here. Bergher also noted that the current octane multiplier ratio of a car can be datalogged on the Accessport. This will allow users to know if there car is down on power because of a bad tank of gas, or even something as simple as filling up with the wrong fuel grade. An OAR of -1 signifies that the engine is operating at maximum performance, and not compensating for fuel deficiencies by pulling ignition timing.

At the end of the day, the overall quality of all three stage kits, the sophistication of the electronic components and the day-to-day improvement in the car’s performance, left us feeling pretty good.