It’s easy to take a lot of modern technology for granted, especially when it comes to automobiles. Air is combined with a volatile fluid, an explosion happens, and somehow movement of a two-ton rolling piece of metal, plastic and rubber is accomplished. It shouldn’t work, but it does.

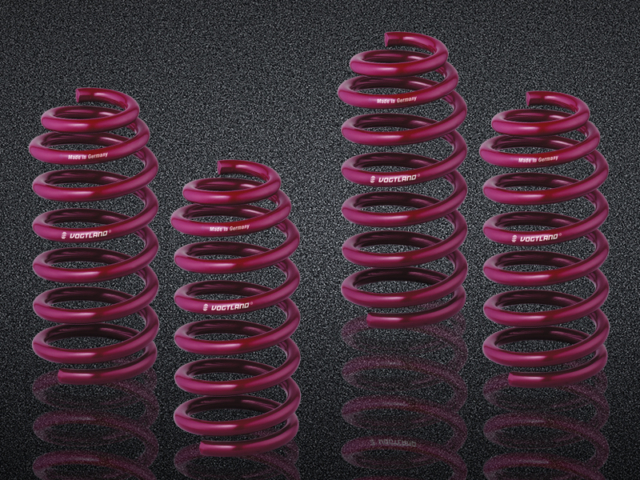

Suspension components – and coil springs in particular – are another element of the automotive equation that’s an engineering feat in its own right. In this clip, German performance suspension maker Vogtland takes us through an overview of the manufacturing process of a coil spring and how a bare, straight piece of metal wire goes from raw material to the finished product.

While most of the text is in German, we’re able to point out some of the particulars of their design and construction process – like how Vogtland manufactures their springs in Germany using an exclusive chrome silicone alloy.

While most of the text is in German, we’re able to point out some of the particulars of their design and construction process – like how Vogtland manufactures their springs in Germany using an exclusive chrome silicone alloy.

The company says this special alloy allows their engineers to design the lightest possible springs to help reduce unsprung weight for improved handling and performance. They’re also engineered provide more travel and are reportedly up to 35% lighter than conventional chrome silicon alloy suspension springs.

Vogtland’s post-coiling process includes tempering, shotpeening and a multi-stage presetting procedure before the springs are phosphated and powder coated to provide a corrosion barrier and some bolstered aesthetics.

The company also touts says they also utilize the most current generation Instron spring testing equipment ensure that each product’s spring rate is within 2% of nominal. Check out how it all works together in the video above.