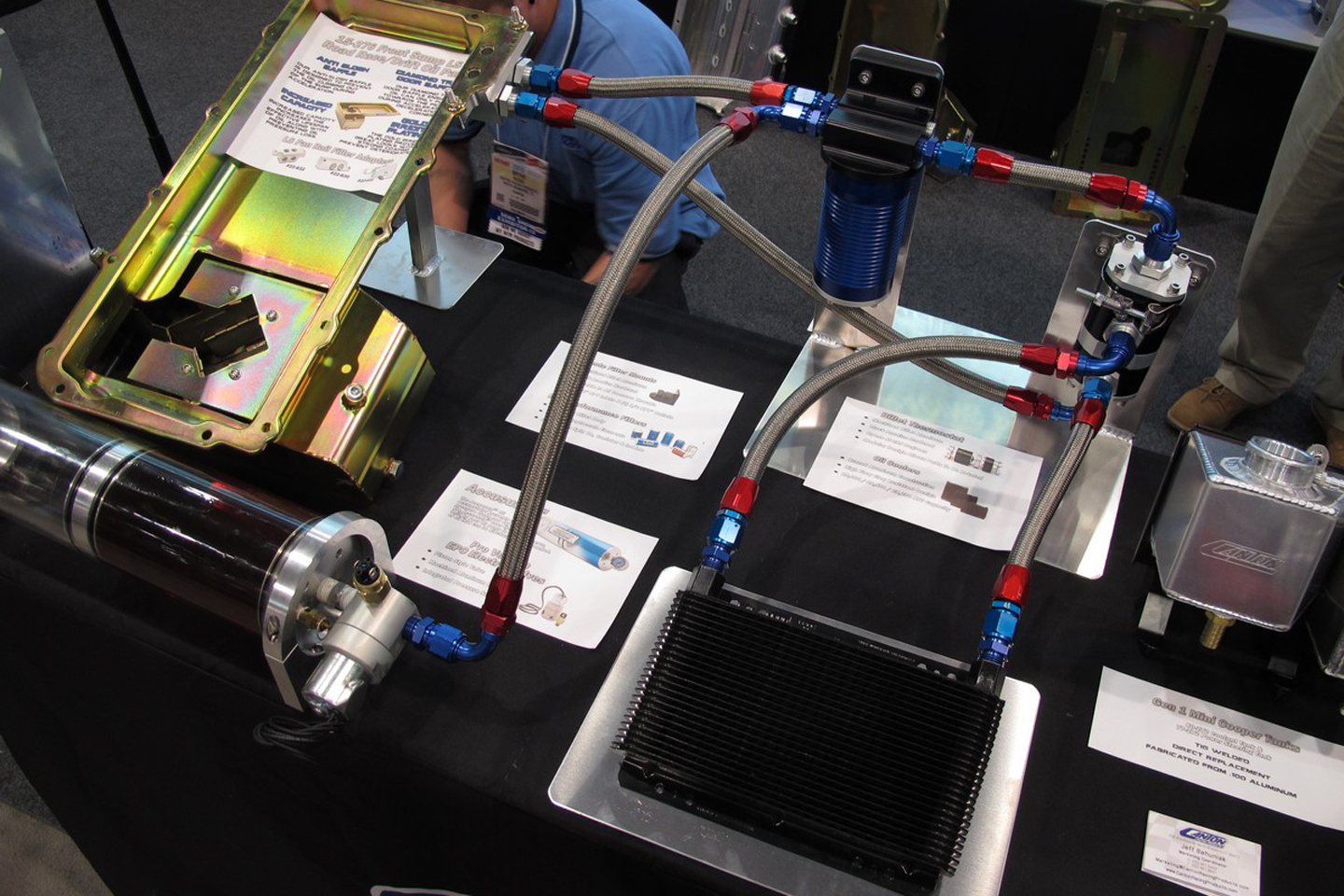

Twenty years ago Jim Jordan founded QA1 Precision Products, a company that initially focussed on manufacturing rod ends and spherical bearings. Through a series of acquisitions in the years that followed the company has expanded to offer a much larger line of suspension components. We recently came across one of the company’s YouTube videos that takes viewers on a brief tour of the QA1 headquarters and Fab shop located in Lakeville, Minnesota.

In 1998 QA1 acquired HAL shocks, and in 2001 introduced their own line of circle track shocks. QA1 has put a great deal of time and effort into engineering their own shock designs and technology as well. As recently as 2011 they also acquired all of the Edelbrock suspension lineup, as well as CAP auto. QA1 builds 50,000 shocks per year, giving them a massive marketplace presence as well.

In 1998 QA1 acquired HAL shocks, and in 2001 introduced their own line of circle track shocks. QA1 has put a great deal of time and effort into engineering their own shock designs and technology as well. As recently as 2011 they also acquired all of the Edelbrock suspension lineup, as well as CAP auto. QA1 builds 50,000 shocks per year, giving them a massive marketplace presence as well.

QA1 today remains a large supplier of spherical bearings and rod ends to manufacturers of everything from lawn and garden equipment, to suspension component suppliers for street and racing parts.

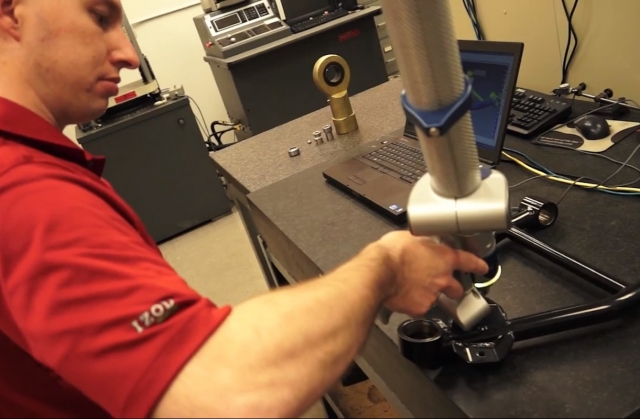

Through the video we find out that QA1 stocks over 5,000 rod end SKU’s (part numbers) on the shelf, which equates to hundreds-of-thousands of parts that are ready to ship every day. All of QA1’s suspension components and rebuildable shocks and struts are manufactured in house at their Lakeville, MN facility.

QA1 builds over 50,000 shocks per year

The main facility also contains a R&D center where new designs and parts are test fitted to real vehicles as part of the quality control process. The fab shop contains various equipment for building some of the lower volume parts as well, here we find CNC controlled tubing benders, laser cut press brakes, and workers assembling and welding new components together.

QA1 continues to strive towards offering a quality product at an affordable price. Their engineering and quality controls help ensure that this American company building products in the USA will be a presence in the street and racing markets for years to come.