So, what exactly does it take to get 400 horsepower per cylinder from a Honda K24 engine? Meticulous assembly and attention to detail. 4 Piston Racing’s recent video showcasing the assembly of one of their K24-KT1200 SFWD and Outlaw Class race engines is something that needs to be watched, even if you are not an import fan. The details are intense, from the precision tools used to dial in every parameter to the parts used; this is an incredible feat of engineering.

Assembly begins with a series of measurements, including the crank journals, which are measured with the bearings in place and the main cap girdle installed and torqued to spec.

The process starts off with the basic setup and layout of the K24’s parts being tested, such as measuring the crank journals and setting up the rings for gapping. They are not doing anything differently from what you would do in any other engine build. The difference is that they do all the things to a finer degree than most. One of the things we first noticed is that they are not using a typical kitchen scale to weigh the rods and pistons, instead they use an Ohaus precision scale (these scales are a couple grand), which are the most precise scales available, used for weighing gemstones, and the like — that is true precision. Not only do they weigh each rod and piston, but they also weigh the rings and bearings per cylinder.

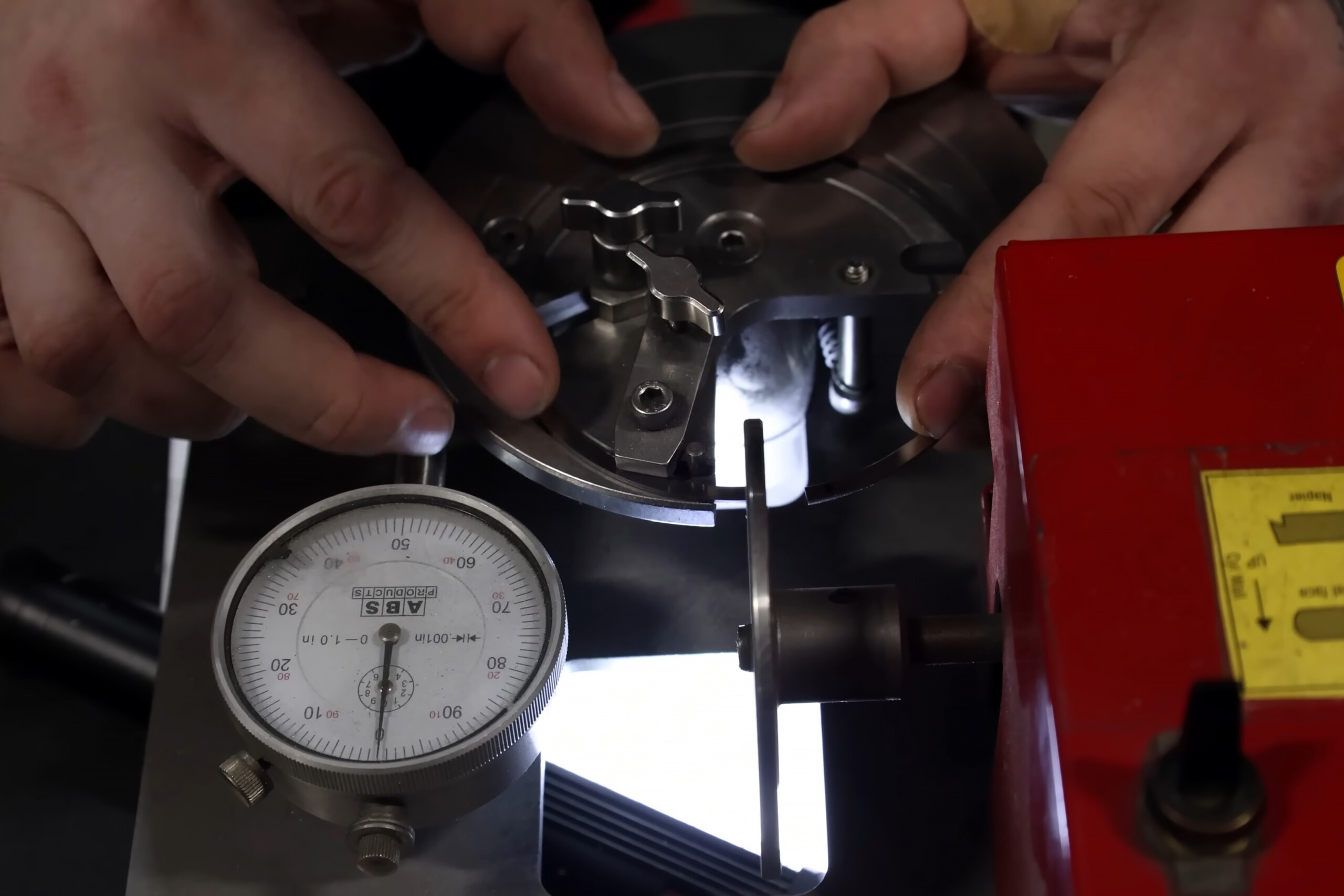

With the girdle still mounted, the rings are checked for gap. 4Piston Racing uses an electric ring grinder that measures how much is being removed for superior accuracy.

When you build an engine at home, or even in a machine shop, how often do you check and grind the oil control rings? Have you EVER gapped the oil rings? 4Piston Racing does it on every single build, and they do it with the main girdle torqued, which is the right way to do it, as the cylinders can distort minutely. When you are trying to extract every possible crin (the technical term for horse hair) of power, you need every component to be exact. Before grinding each ring, the machine is zeroed with a dial indicator to ensure each ring is cut to the exact necessary spec. There is no guesswork here; zero, zilch.

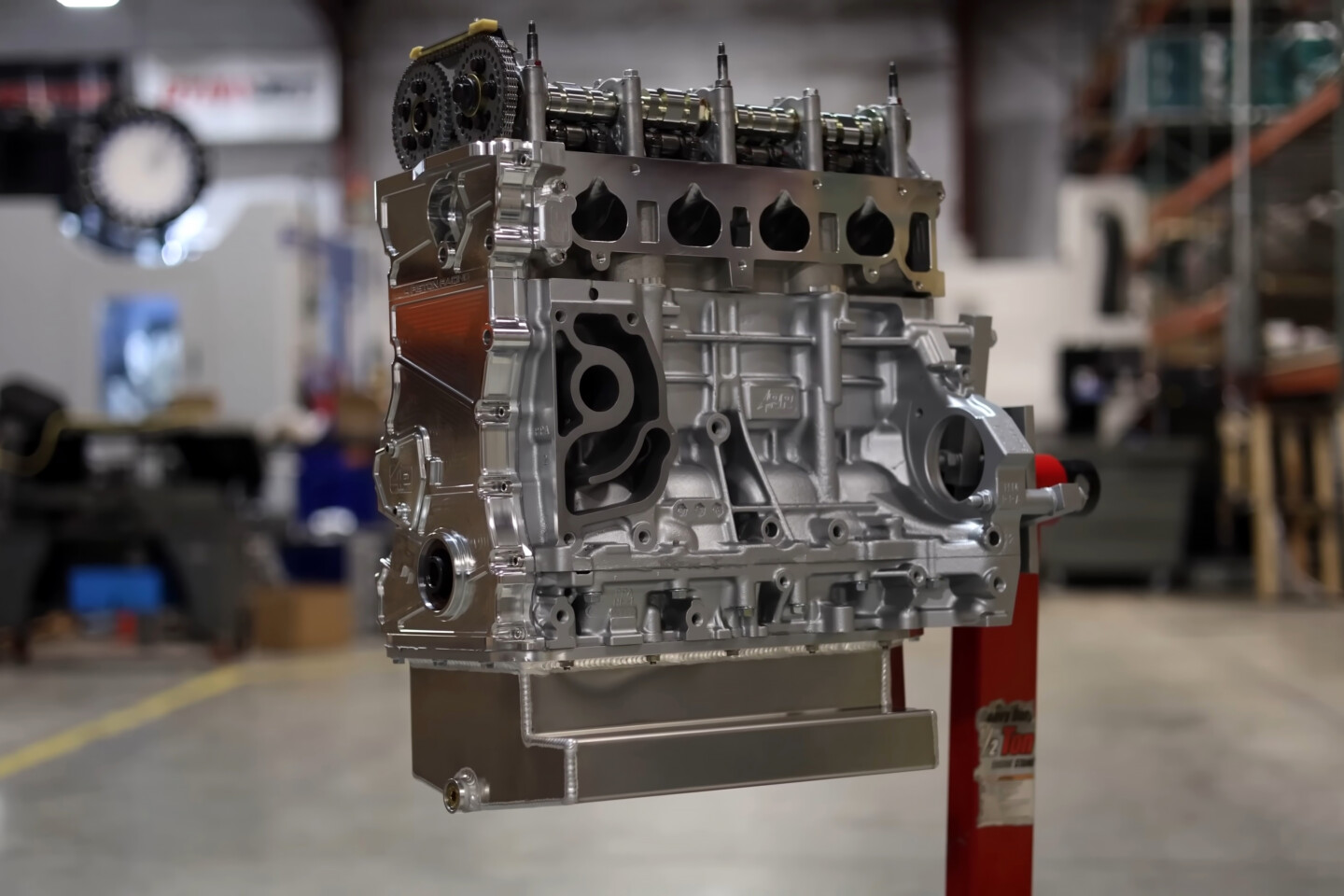

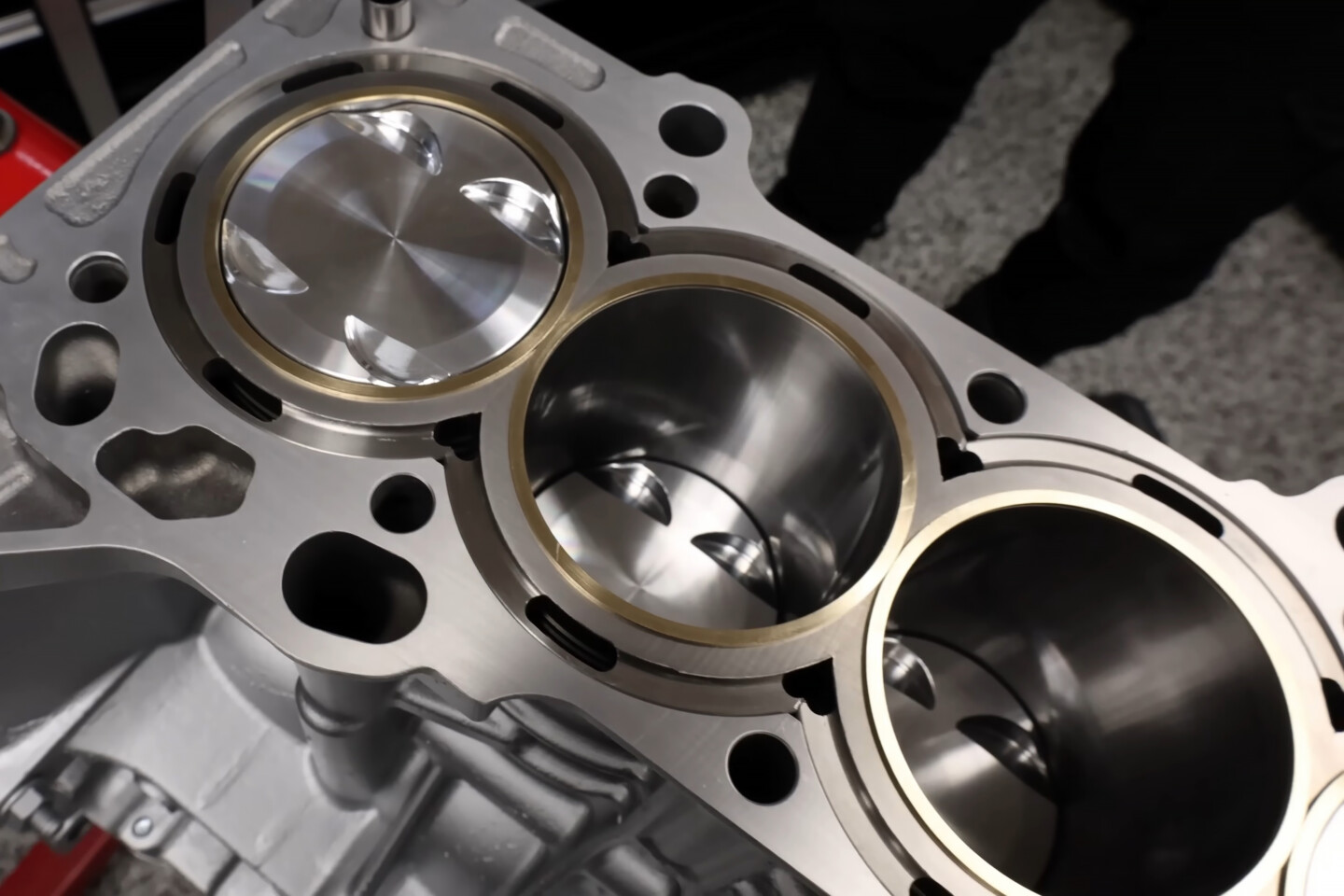

The rotating assembly is all billet, assembled by hand using precision fixtures. The rods are 100 grams lighter than the closest steel rod, making this an incredibly lightweight assembly capable of spinning over 11,000 rpm. The block assembly is equally as clean. You can see the crank bearing setup and crank being installed in a full laboratory setting. You would think they were working with Ebola instead of a 1,600-horsepower four-cylinder, but the only thing viral with this engine is the video.

This is not a garage build, they don’t soak the pistons in ATF before installing them into the engine. Using precision oil placement, each piston is hand-lubed and dropped into the block by hand, no hammer needed. The same precision oiling is used for the main cap bolts. When you buy a 4Piston Racing engine, you are buying meticulous engineering in the guise of an engine. This is hypercar stuff, you don’t see this level of detail in production-line anything.

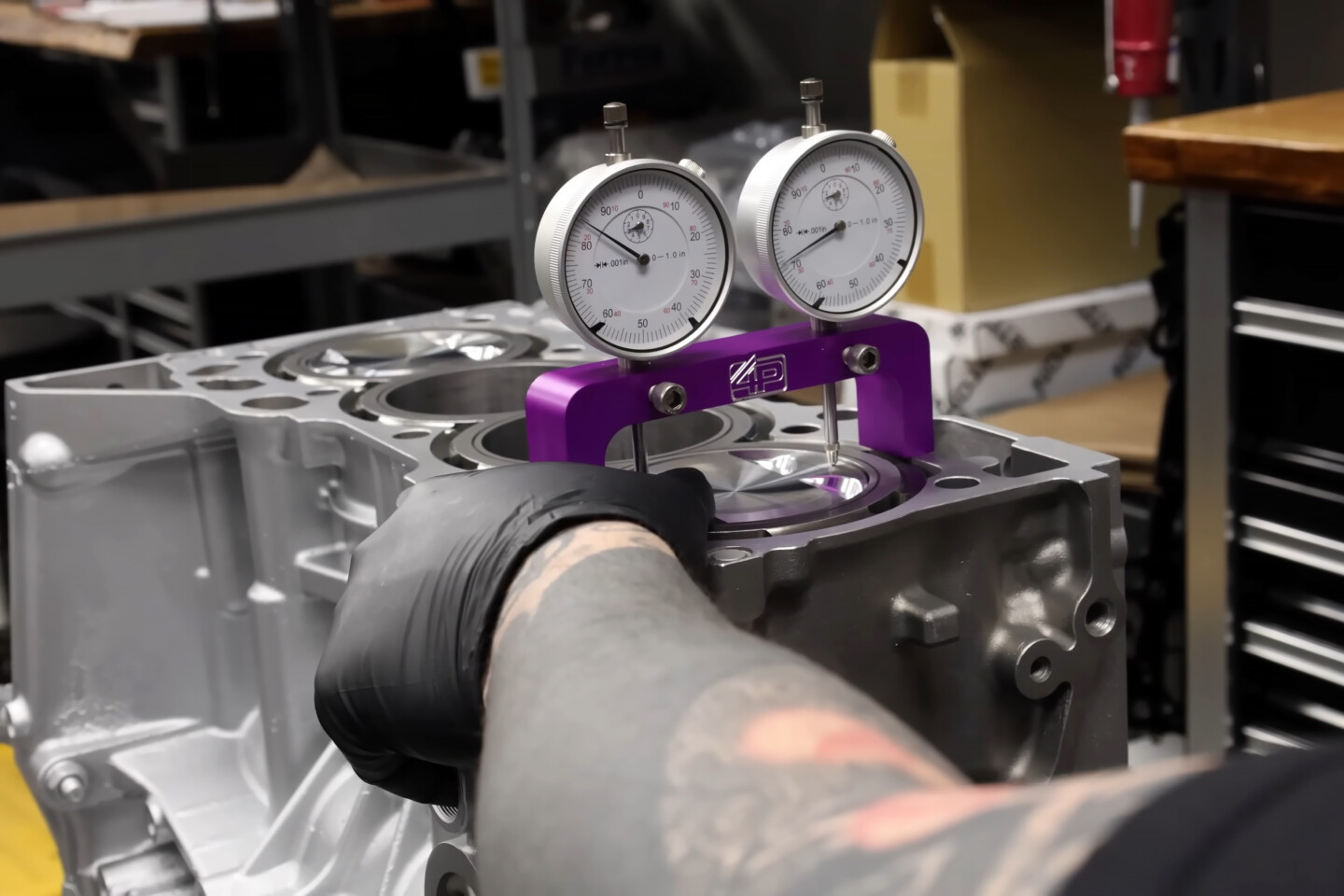

Precision is key, so each piston is checked for deck clearance before moving on. This is a “check, check, and re-check” situation, to ensure no goof was made in the process.

After assembling the K24 rotating assembly, each piston is checked for deck clearance, and the rods are measured for side clearance. While this is recommended for all builds, at this power level, the slightest amount of play or tightness matters to the ten-thousandth of an inch. The same level of detail runs throughout the build of this engine, as each moving part is assembled, it gets checked for clearance and performance. The timing chain is installed using three dial indicators to verify the cams are perfectly timed with the crank and each other; no eyeballing the timing marks here. Every valve spring is tested to ensure they all match and are then installed with a manual spring compressor.

Before the head goes down, the fire rings were placed on the block, then a copper gasket, and then the head.

Once the valves are installed, each port is pressure tested to verify the seal. A copper head gasket goes down over the K24’s fire rings on each cylinder, then the head studs are installed before the head is lowered onto the block and torqued. Next, the valvetrain is loaded onto the head. Before tightening the cam caps, each rocker arm adjuster is fully loosened so that there is zero load on any lobe, ensuring accurate torque specs are reached. Each rocker is adjusted with feeler gauges. This is another precision measurement that should be done for all engine builds, but is absolutely critical at this level of performance.

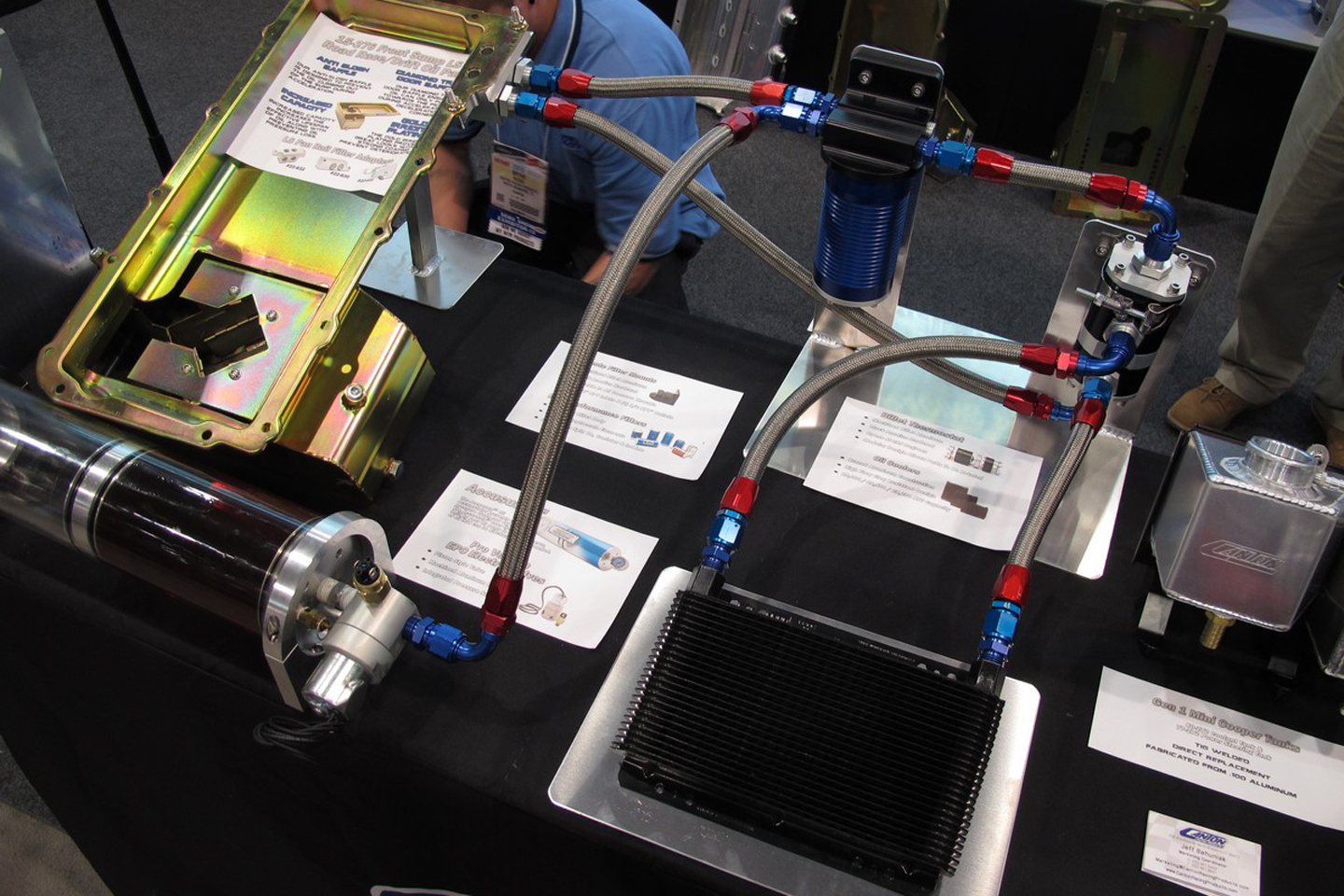

The covers are assembled with gray RTV, which is designed to bond the components together, as these are stress members of the engine. Nearly every component in this engine was built by or specifically for 4 Piston Racing, to their specs.

This K24 engine could easily be a showroom display piece, as it is beautifully machined and assembled, but that would be a colossal waste of engineering. The highest rating on a stock K24 was 205 horsepower from the K24A variant. 4Piston Racing manages to eek out 7.88 times that with their 1,600-horsepower 11,500-rpm screamer. Regardless of whether you like imports or prefer big American V8s, you simply have to respect the engineering that goes into building a 400-horsepower-per-cylinder anything. You certainly don’t see many 3,200-horsepower LS engines.