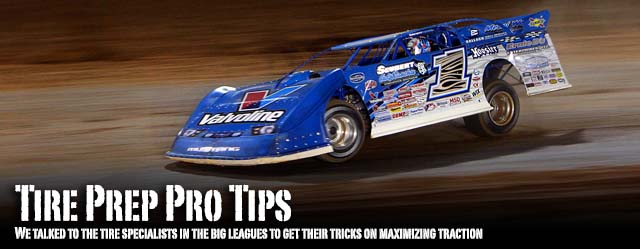

In racing classes where the rules allow it, properly prepping the tires on your race car can be the difference between victory and a mid-pack finish.

In racing classes where the rules allow it, properly prepping the tires on your race car can be the difference between victory and a mid-pack finish.

But getting it right is easier said than done. If you are moving up from a class where you aren’t allowed to do much more than put air in the tires, setting up an efficient tire prep program can be overwhelming. Most of us understand the concept of siping and grooving (if you don’t, check the sidebar before going further), but that’s just the basics. So what’s better, more grooves in a hard-compound tire or fewer grooves in a softer tire? Should the sipes be cut laterally across the tire, longitudinally around the tire, or both?

So What's Grooving And Siping?

Grooving and siping are similar but defiinitely not the same. Here’s a down-and-dirty breakdown:

Grooving is the act of cutting channels in the surface of the tire. Typically they are around 3/16 of an inch or so wide and cut with a heated blade. Grooving a tire creates multiple edges for the tire to help grab the track and can help improve traction, especially on loose, dry tracks.

Siping is also cutting the surface of the tire, but instead of creating a tread pattern, when you sipe a tire you are only cutting slits in the rubber. The slits may not look like much, but they serve multiple purposes. When the car first hits the track, the sipes help the tire heat up faster. But once the tire is up to temperature, the sipes will “open up” and then keep it from overheating and loosing traction. Sipes generally help improve traction but also will increase tire wear, so how much you choose to sipe any tire will often become a balancing act between traction and durability.

The biggest factor when determining how to prep your tires obvously will be track conditions. Both Miller and Duncan gave the same general guidelines for compound and cutting choices here. Slimy or muddy tracks require a soft compound tire with lots of grooving to give the tire more edges to bite into the track’s surface. Wider grooves in this situation–versus sipes–are also better at slinging off any mud trapped between the tread blocks so that the grooves are open and ready to bite into the track again. A race tire that cakes with mud in the grooves is practically useless.

More grooves are also helpful if the track gets rough, rutted or otherwise starts breaking up. The extra grooves will effectively “soften” the tread blocks so that they can conform to the track surface and help provide grip.

Even a world-class driver like Rick Eckert (24) can’t do much with a set of tires that aren’t properly matched to the track conditions.

If, however, the track rubbers up and starts providing a ton of grip, you will run into an issue where you can actually start tearing the rubber from the tire. This is called “chunking” and it most often happens if the tire is over-siped, or the sipes are too deep. Generally, you want your sipes to be no deeper than about half the depth of the tread block. If you need some sipes to help keep the heat out of a tire on a high-grip track, try siping the tire radially only (versus across the width of the tire). This helps control heat without adding too much stress to the tire.

Really abrasive tracks typically require the least work. An abrasive track will function a lot like an asphalt track. In this situation, you want the rubber to do the work, so minimal grooving and siping will not only help traction but will also help the tire last longer.

On the other end of the spectrum, when the track gets slick or glazes over, that’s when you will need to get busy working on your tires. If the track is slick you will need to do everything you can to help the tire get traction. Just be careful, if the driver is spinning the rear tires too much, that will also generate heat which will case of heavily siped tire to break down.

Once again, we have to stress that these are only general guidelines. Both Miller and Duncan say that the greatest teacher when it comes to tire prep is experience. Make sure to keep a close eye on the race track to be prepared for how it will change as the night–and the racing–progresses. If you aren’t the driver, make sure to talk to him or her regularly to see what they are feeling from the driver’s seat. And try to develop relationships with the veterans at your track or in your series. You may run into a couple that wouldn’t help their own mother out of a ditch, but for the most part the dirt racing community looks out for its own and other racers or crewmen can be a valuable resource.

Finally, make sure to check out our video interview with Cody Duncan (just above), who has been working with the Rocket house cars for a few years now. And please make sure to share any tips you may have in the comments below. We’d love to hear how you handle your tire prep!

Bob Miller, tire specialist for Rick Eckert Racing, says you have to get used to spending time with a grinder. After just a few laps, the edges of the grooves will become rounded and give less bite. If you plan to reuse tires after practice or the heats, cleaning up the surface using an electric grinder with 36 grit sandpaper will help sharpen up the edges on the tread blocks.

Dirt tire manufacturers like Hoosier and Goodyear offer a wide variety of tires, not only compounds but also tread patterns, to give you plenty of room to work when it comes to creating your own grooving and siping secret recipe. Miller and Duncan say they will often prepare 10 different sets of tires for a weekend of racing at a track they are familiar with. More for unfamiliar conditions.

Cody Duncan grooves a tire that will soon find its way on Josh Richard’s #1 Rocket Car. Grooves are wider than sipes and help create edges on the tread blocks that “bite” into the track surface.You can see that some of the rubber is still in the freshly cut grooves and will have to be pulled out by hand.

Cutting grooves on a diagonal on your front tires can help improve traction in the turns when the drive is hard on the wheel. After all, maximizing traction when the car is going down the straights and the wheels are pointed straight ahead isn’t really the point.

A siping tool holds multiple razor blades to help ease the work load when siping a set of tires. Generally, you want to set the blade depth so that they cut no more than half way though the depth of the tread block.

This tire has been heaviy grooved and siped and is ready for a situation where maximum traction is called for.

This tire has been cut with minimal grooves across the width of the tire and sipes running only along the radius (called “going with” the tire). This can be helpful to help control heat buildup in an abrasive, high-traction race track without overly stressing the tire.

This is what happens when high horsepower and lots of grip combine to overpower a tire. This tire shows an extreme amount of chunking, but it held up through the feature and did its job.