The guys over at 1320video made their way down to Pac Performance in Australia which is a mecca of insane rotary builds. This was the last full day in Australia for 1320 and they start off with arriving at Pac Performance for a shop tour. After scooting past a yellow trailer in the front, the shop parking lot reveals nearly a dozen engines being unloaded with lots of project cars occupying parking spaces. George of Pac Performance tells the 1320 crew that they received 73 engines the week before, meaning this this shop deals with a lot of engine work. To top that off, it’s mentioned that the majority of engines they have shipped in are used in project and customer car builds that they do in house.

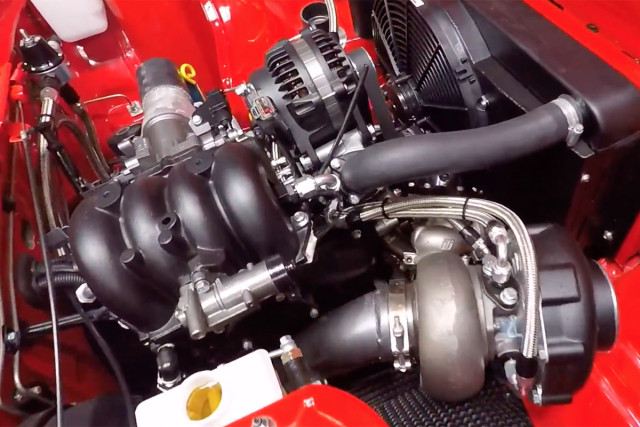

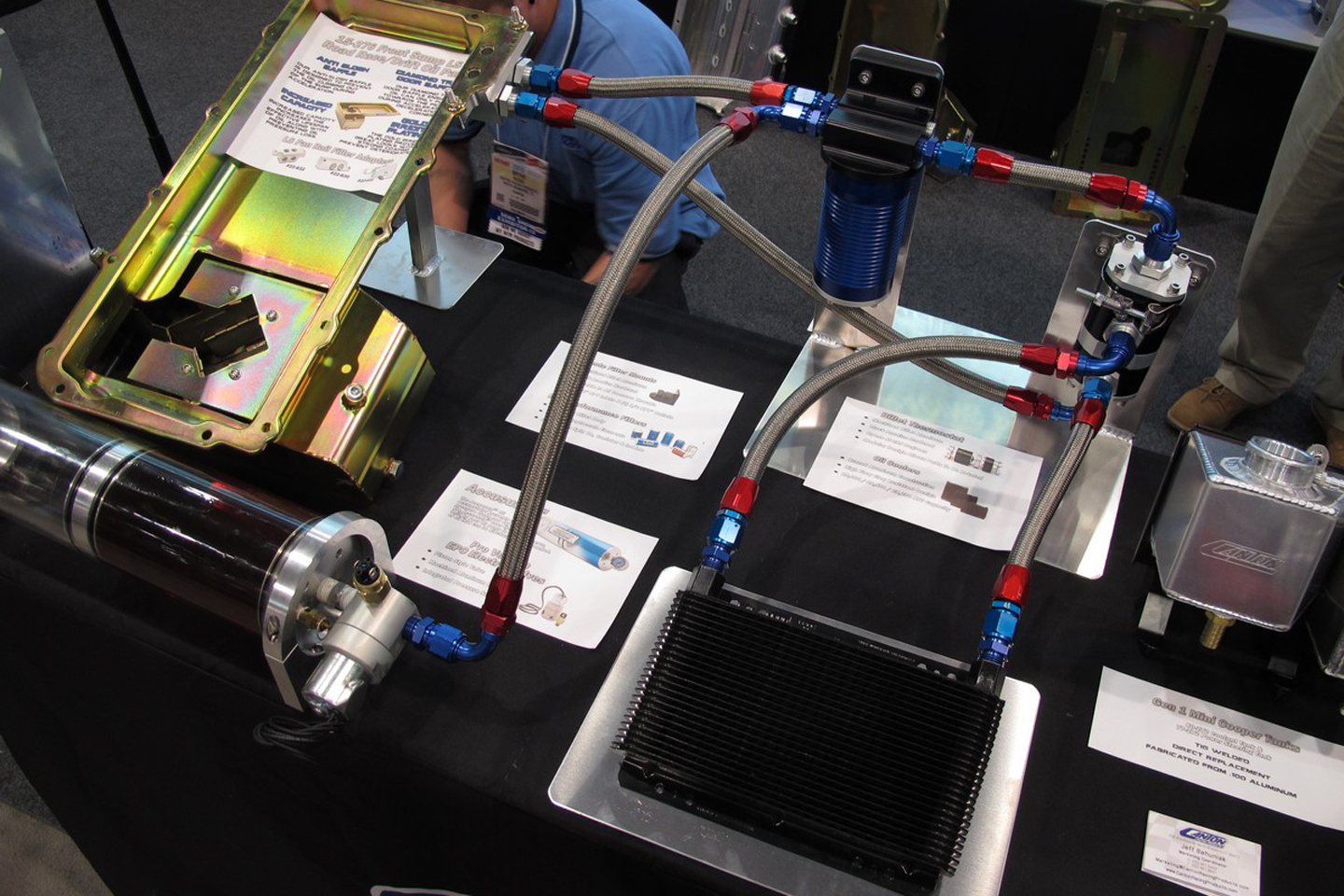

Pretty quickly, they move inside to the actual shop area which is filled with a lot of colorful cars–some project cars, but many customer rides. After a quick peak inside the shop, Rocky is introduced, who is working in the corner room assembling engines. Rocky leads the crew outside to start checking out some of the builds going on in the shop. Impressively they don’t just build rotary engines, they make lots of parts including brakes, calipers, tie rods, steering components and anything else they need. To Pac Performance street cars aren’t just cars that can be driven on the street in a pinch, they’re cars that owners drive to and from the track in comfort since the few “street cars” they show off have full interiors and large gas tanks to make cruising with friends not only possibly, but enjoyable.

One big goal goal they’ve got for builds that they do for customers is making sure cars leave making great power and are reliable. Reliability from a rotary? Yup, Rocky tells us that many cars they build are actually used on the street, to the track, and back home again. “They don’t have to just go good, they’ve got to look good. They’ve gotta be functional and handle, and stop well, and run without overheating.” says Rocky.