Depending on who you are, when you look at an engineering masterpiece such as a Formula One car, we tend to look at it as a whole, or in segments like aero, chassis, and engine. We never really take the time to appreciate the individual components that make up these amazing machines, which would not exist without them.

The Red Bull Racing team designs and produces over a million parts for their Formula One cars every year, which makes them uniquely positioned to fully appreciate the work that each individual component puts in at every race. The team created the video above – detailing the life of a front suspension bolt.

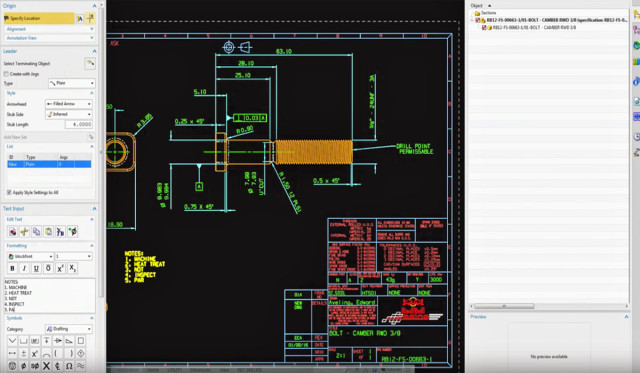

The story begins with a member of Red Bull’s engineering team drawing up the initial hand sketch of the fastener, marking its inception. The journey continues as the hand sketch is then recreated as a CAD blueprint using extreme detail, where the data is then given to their team of talented machinists.

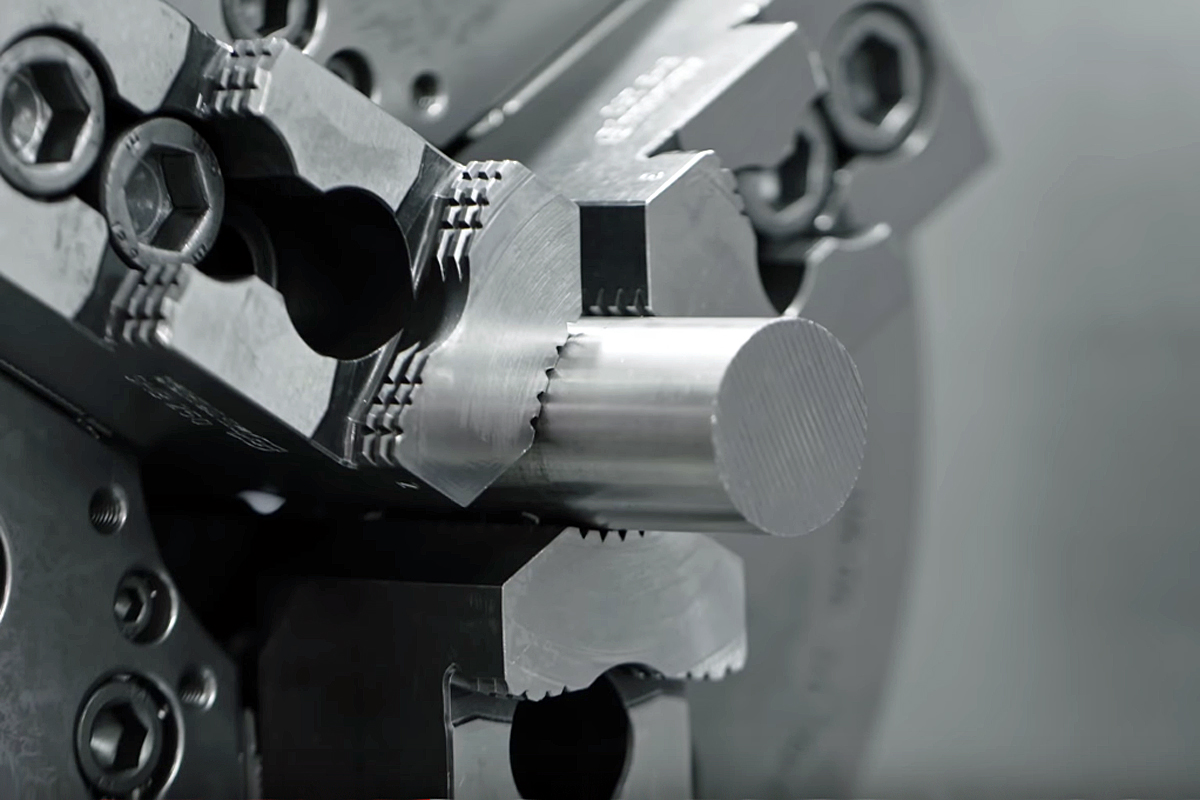

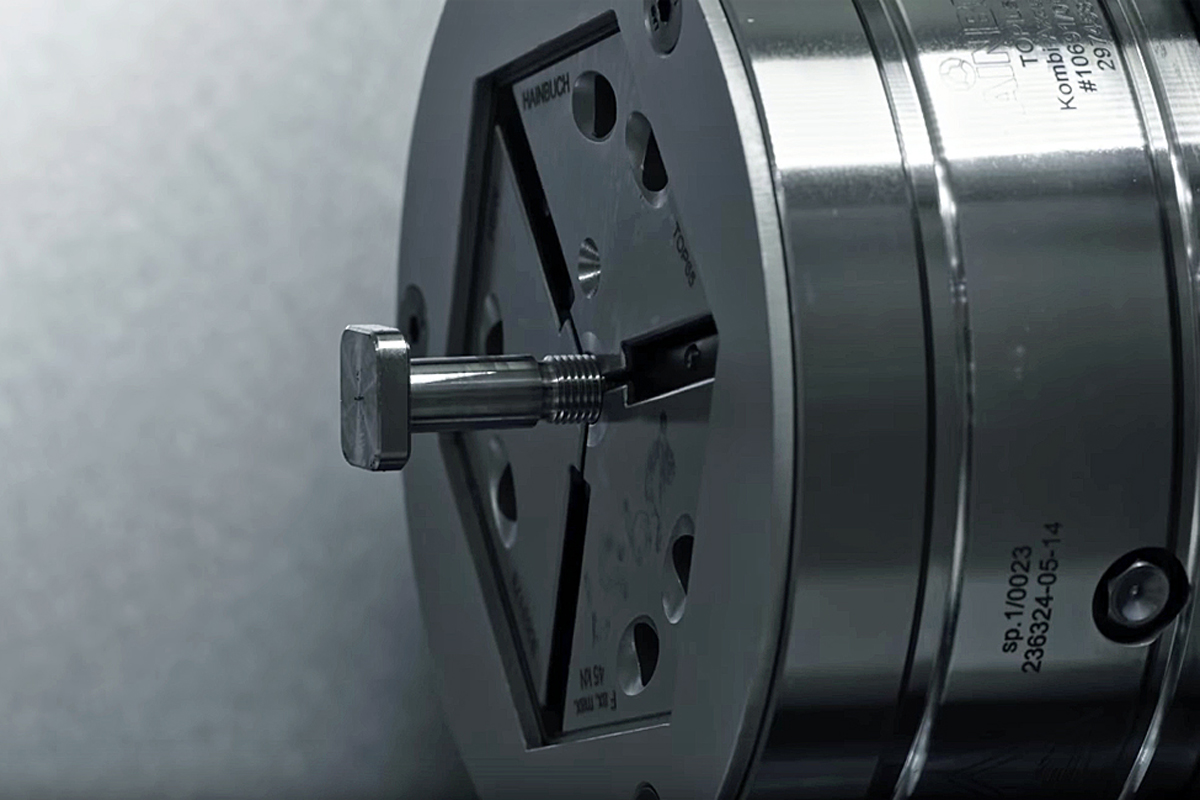

Once in the possession of their machinists, the proper raw bar stock is pulled from a rack, measured, and cut to size; where the bar stock is then placed in the rotary table jaws and the machinist enters the numeric controlled programming codes to command the multi-axis CNC machine to begin cutting and carving it to shape.

After the CNC process is complete, the bolt is put through an inspection process involving microscopes and micrometers, chemical and heat treating, and finally laser etched with its name – RB12-FS-00663-02.

Red Bull Racing’s video does a great job of displaying the the manpower required to produce even a single 60 mm bolt. The high level of detail and care taken throughout every step really proves just how important even the most basic fastener is to the racecar as a whole.