Although the Ford Focus RS RX race car may be built upon one of the most popular compact car platforms on the planet, it bares little in common with the street legal Focus RS that it shares a name and platform with. It took the combined efforts of Ford Performance, M-Sport, and Ken Block’s Hoonigan Racing Division to up the ante on the Focus RS from hot hatch road monster to rally-ready race car.

The second part of Ford’s mini-documentary, “Project RX”, focuses on the fabrication and assembly of Ken Block’s racing machine, and it involves a lot more than you first realize.

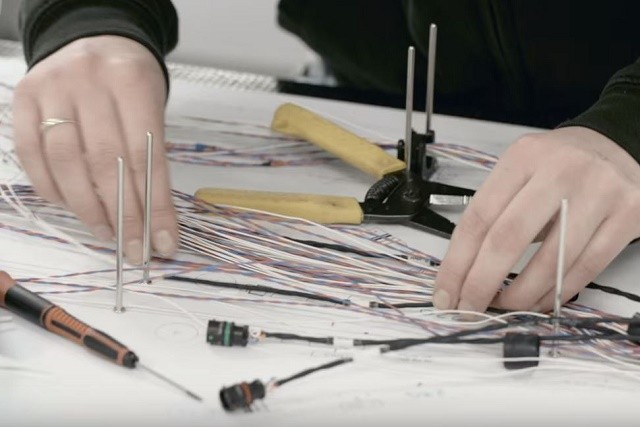

For example, the custom wiring loom that links the RS RX’s 600 horsepower EcoBoost engine to its dynamic all-wheel drive system has to be spliced together into a loom by hand. As in, from scratch, laying out every single wire to every single component in a car that has far more processing power than your typical desktop. This task falls to Nicola Olley, one of M-Sports loom technicians, who takes a particular pride in gathering all the wiring together into one nicely packaged, shrink-wrapped harness at the end.

In an age where plug-and-play is taken for granted, it’s a helpful reminder of what goes into building custom speed machines like the RX. Then there’s Craig Henderson, an M-Sport electrical engineer in charge of putting together the fancy gauge clusters and switchboards that control Ken Block’s Hoonigan machine. No small task considering how much gadgetry goes into these modern cars.

In an age where plug-and-play is taken for granted, it’s a helpful reminder of what goes into building custom speed machines like the RX. Then there’s Craig Henderson, an M-Sport electrical engineer in charge of putting together the fancy gauge clusters and switchboards that control Ken Block’s Hoonigan machine. No small task considering how much gadgetry goes into these modern cars.

Meanwhile, on the other side of the Atlantic, the Ford Performance team in Michigan has to put together the aerodynamic body package for the RX. Vehicle Dynamics Engineer Sage Wolfe discusses how, when putting together all the components, one has to take into account things like suppliers and access to equipment on tight deadlines. When everything basically has to be made by hand, there’s not a lot of room for error.

There are two more videos in the Project RX series, and if you haven’t already, make sure to check out part one right away.