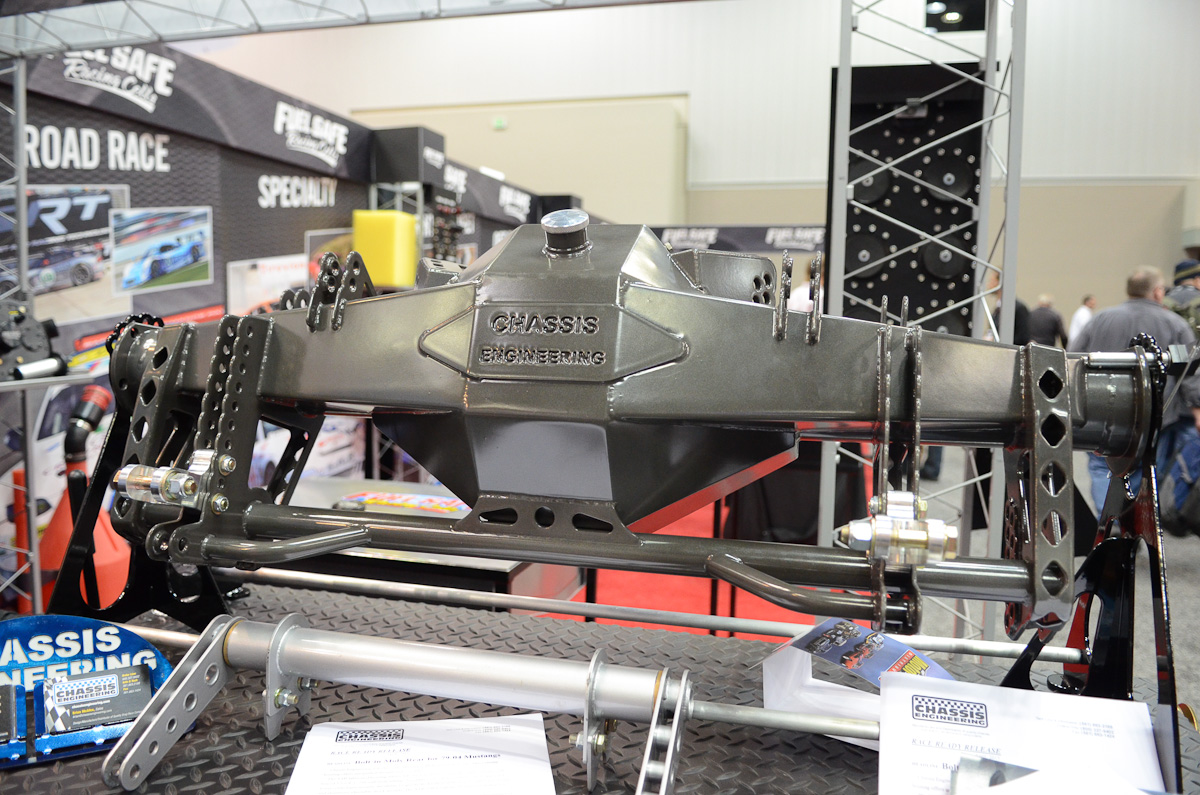

There are no two things in drag racing that go hand-in-hand more than small-tire racing and Ford Mustangs, and for that very reason, manufacturers like Chassis Engineering have and continue to develop new products just for that niche but highly popular market.

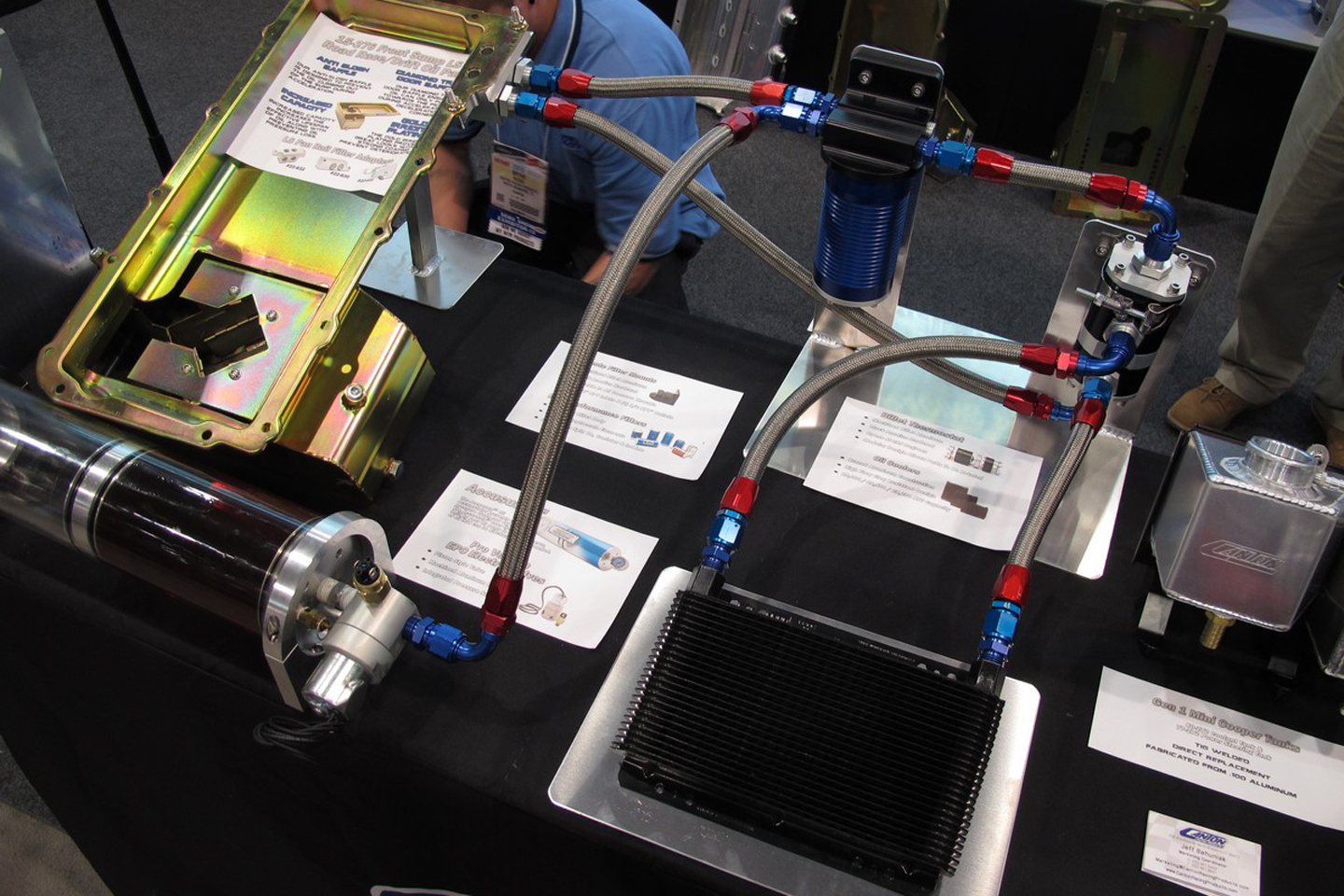

Here at PRI, Florida-based Chassis Engineering has pulled the wraps off an all-new rearend housing built specifically for stock-suspension Mustangs that would seem as though it could handle almost anything (even a nuclear winter). And as Clayton Murphy tells us in his explanation of how the new housing is assembled and welded, that’s exactly what they had in mind from the outset.

If you have a car with a really low ride height, as is common in that type of racing, you can still get the lower control arms at the angles you want. – Clayton Murphy, Chassis Engineering

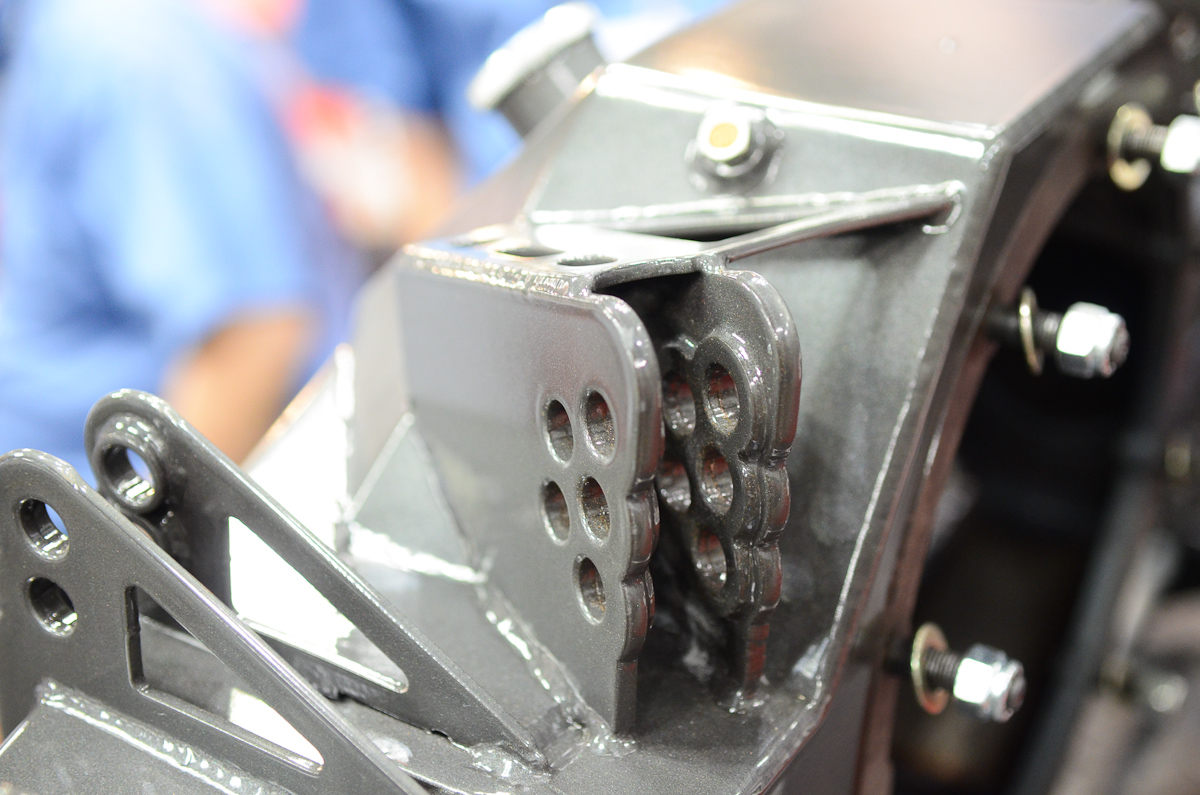

“If you have a car with a really low ride height, as is common in that type of racing, you can still get the lower control arms at the angles you want. The bottom holes are 2.5 inches from the centerline of the housing. The upper brackets can’t be changed as far as width, but the lower brackets, shock mounts, wheel-to-wheel or housing end-to-housing end can be changed,” Murphy tells us.

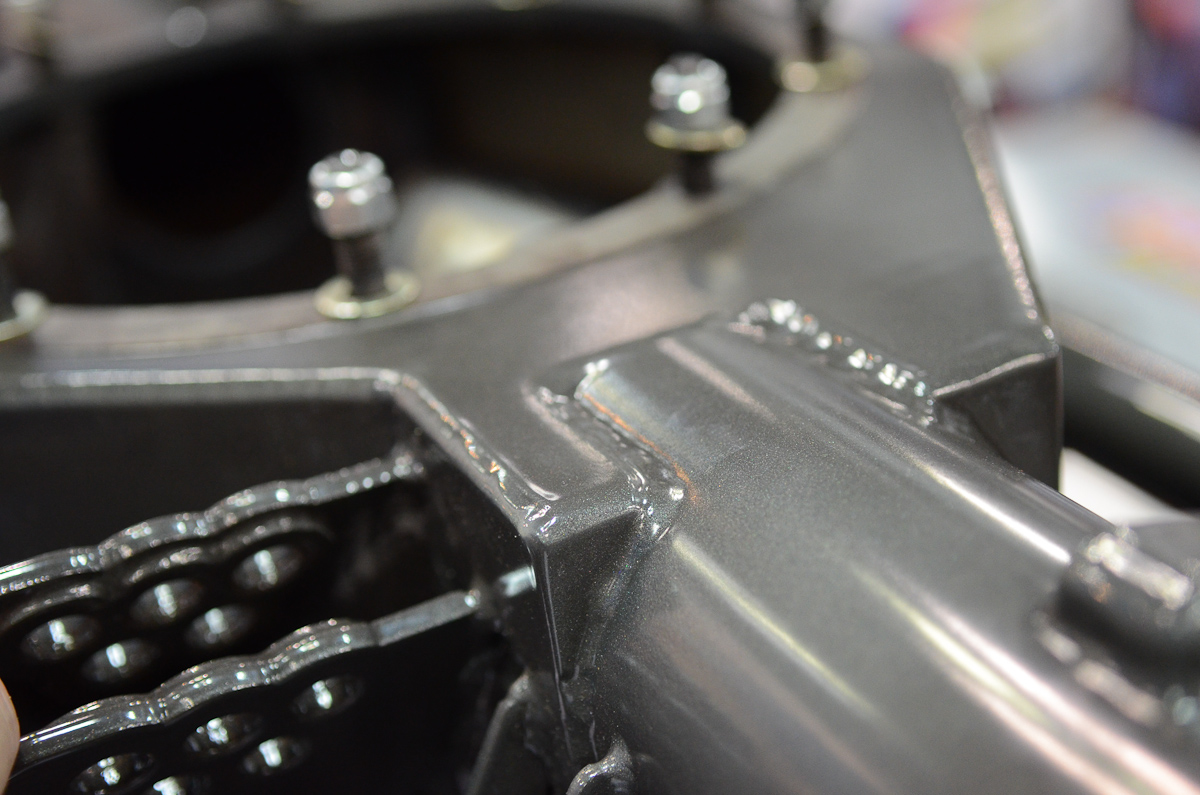

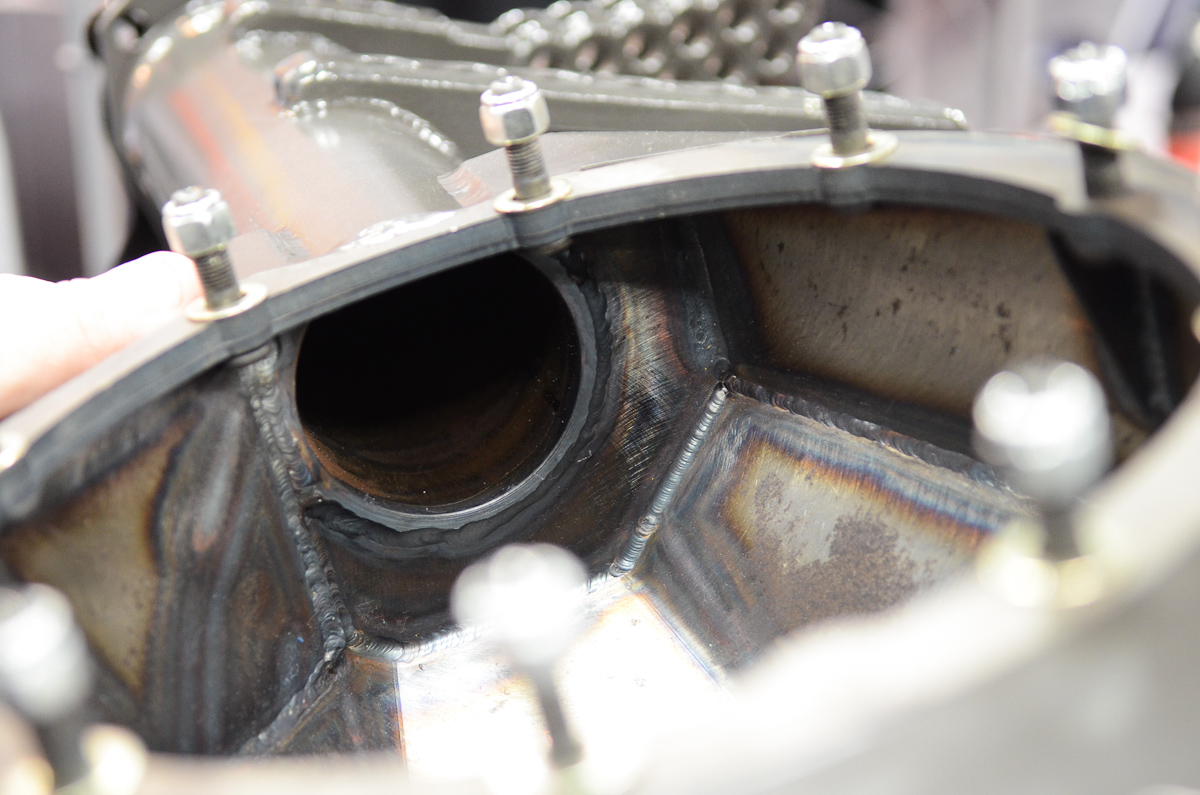

Chassis Engineering has engineered the XTR housing to be as light as they can physically make it — weighing about 68 pounds — but through some clever assembly, is impressively strong. Two internal braces are positioned within the tubes, while the face plate itself it also braced. As Murphy shares, the housing is built upside down, from the face plate up. The sides then go on, followed by the internal braces and then the tubes. An external brace is also added for the tubes. The order of assembly results and the degree of bracing results in a set of axle tubes that will not rotate under any type of abuse.

“The tube itself can’t ever twist or spin; we’ve never had an issue with them bending, either,” says Murphy. “Obviously, in an accident or something, they can bend, but they won’t under normal power application, the way it’s built.”

As Murphy tells us, the housing is designed for stock suspension-style classes, but is similar to a four-link-style setup, as the upper controls arms are converted where there’s a rod end in the back. Chassis Engineering has the housing set up for a 3 1/4, 1/2-inch rod end on the top and bottom for extra adjustability. The top bracket has five holes, and 11 on the bottom. “If you run out of adjustability with this, then you really need to do something else with your car,” he says.