In a normal daily-driven car, clutch wear is not something that is cause for concern. The daily cyclical loading and unloading of the full circle disc does not present accelerated wear, and therefore shortened lifespan. In performance applications however, the clutch system sees far more strain as high-horsepower engagement and slippage is demanded.

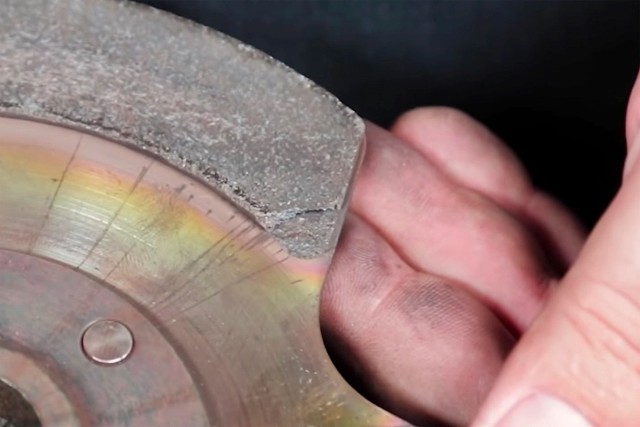

In this video Tilton gives us a look at some of the key areas and considerations to inspect when determining the condition of your multi-disc cerametallic clutch. As a clutch is slipped it produces enormous heat as a byproduct of friction. This heat and overly-aggressive use of the clutch can lead to problems such as friction surface failures and warpage.

When removing a clutch assembly for inspection it is important to note the order and placement of the discs and spacers. In order to retain the factory balance, these parts must be reassembled in the same positions. Make note of any orientation marks. With the assembly laid out, Tilton recommends inspecting the pressure plate assembly including the basket, diaphragm spring, retainer plate and hardware. Scoring or cracking on the basket legs can indicate a bent input shaft or pilot bearing.

When removing a clutch assembly for inspection it is important to note the order and placement of the discs and spacers. In order to retain the factory balance, these parts must be reassembled in the same positions. Make note of any orientation marks. With the assembly laid out, Tilton recommends inspecting the pressure plate assembly including the basket, diaphragm spring, retainer plate and hardware. Scoring or cracking on the basket legs can indicate a bent input shaft or pilot bearing.

The diaphragm spring is what provides all the clamping pressure to put power to the ground. The fingers of this circular spring should be inspected for excessive flattening, heating, or other damage. The hardware and ring retaining the spring should also be checked for tightness.

Moving on to the pressure plates, a feeler gauge should be used to ensure warpage is .008 inches or less, and any debris is cleaned off while retaining the minimum .449 inch thickness. Upon reinstalling the pressure plates into the basket, a minimum of .006 inch clearance is needed between the leg thrust buttons and plate. The clutch discs themselves should be inspected for cracking at the inner spline, and friction material condition. Measuring the clutch disc friction material, ensure no more than .030 inch has worn away from the original thickness and you’re done!

Moving on to the pressure plates, a feeler gauge should be used to ensure warpage is .008 inches or less, and any debris is cleaned off while retaining the minimum .449 inch thickness. Upon reinstalling the pressure plates into the basket, a minimum of .006 inch clearance is needed between the leg thrust buttons and plate. The clutch discs themselves should be inspected for cracking at the inner spline, and friction material condition. Measuring the clutch disc friction material, ensure no more than .030 inch has worn away from the original thickness and you’re done!

Don’t cheat yourself by reassembling worn components with new components. Out of spec parts will cause the surrounding new parts to wear unevenly or at an accelerated rate. If you have questions concerning the condition of your Tilton clutch, contact them here.