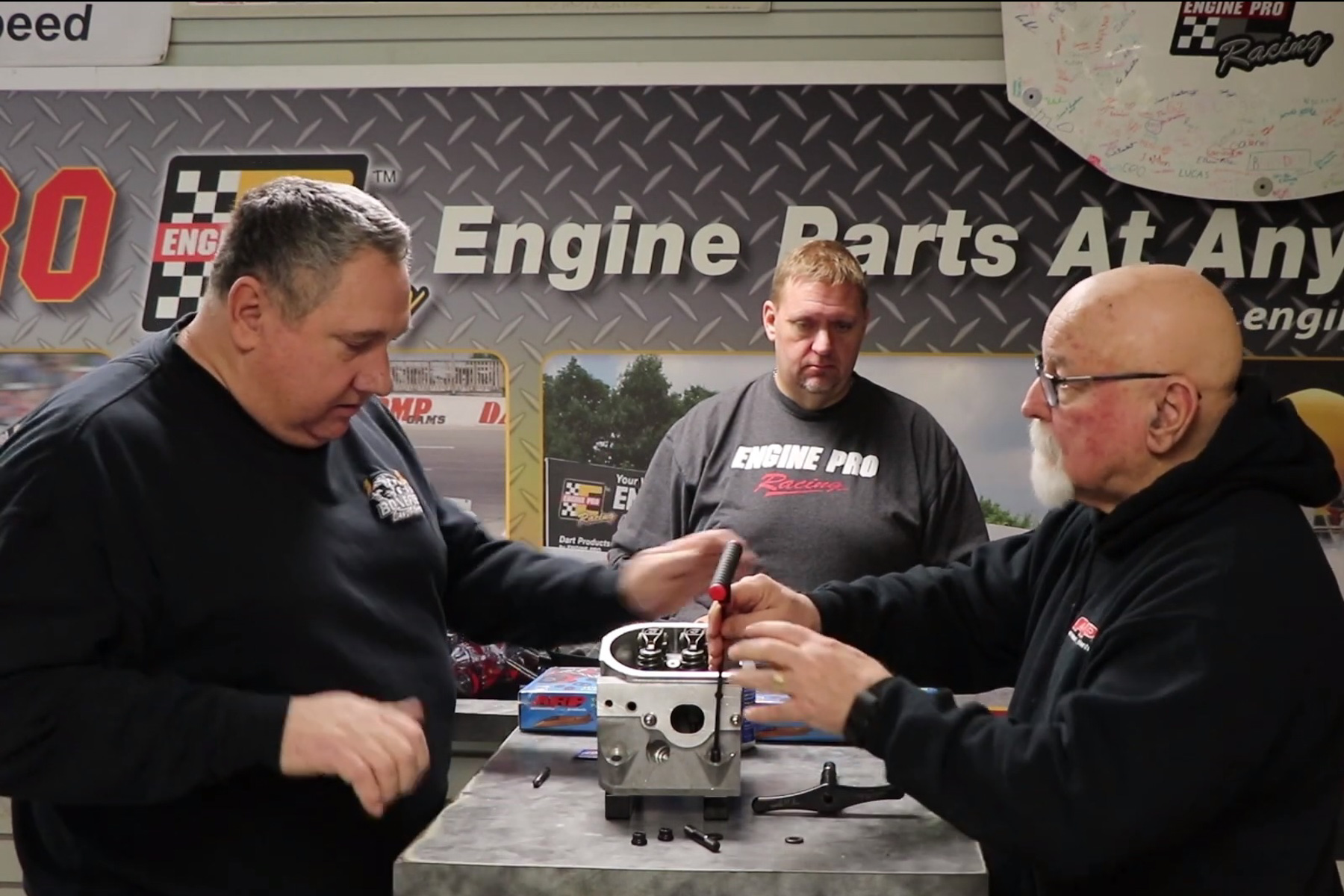

Head studs have an important job with an engine since they’re the glue that keeps the cylinder heads attached to the block as cylinder pressures are trying top force them apart. Installing a set of head studs might seem like a fairly simple task, but there a lot of ways you can make mistakes, and that could cause some issues for your engine build. The team at Engine Pro put together this great video with Mike Cunningham from ARP and Jamie Hamm from Bonified Customs’ to provide builders with some tips on how to install head studs correctly.

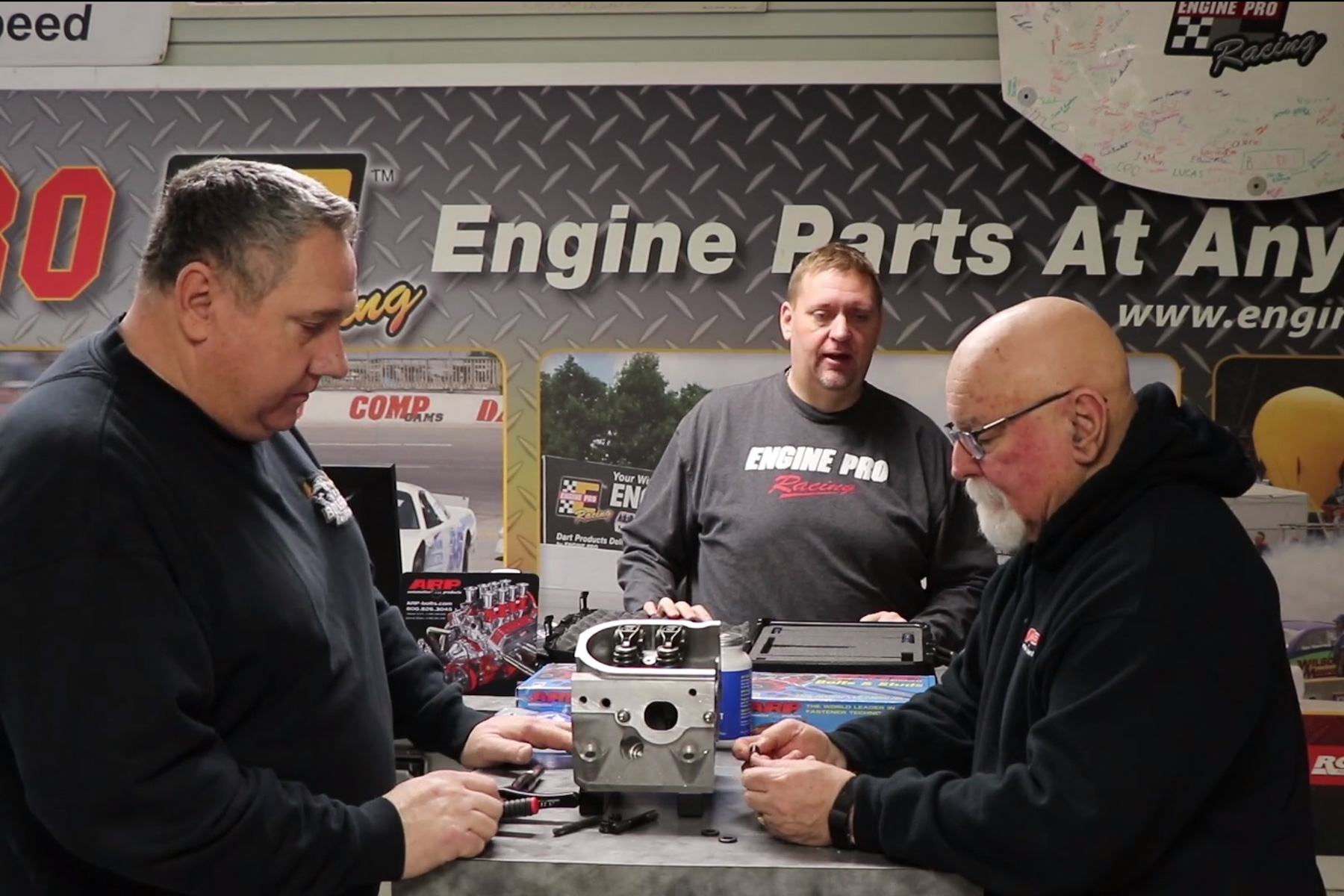

One of the first big tips that Cunningham and Hamm talk about is making sure you read the directions when it comes time to install a set of head studs. There could be some important information covered by the instructions that go beyond just torque specs that are critical to a successful installation. Things like where you apply lubrication, how to avoid bottoming a stud out, and specific features of a stud are all included in the instructions that you need to know about.

Getting head studs in the correction position inside the cylinder head before you begin to torque it down is another subject that’s covered. Cunningham provides some outstanding information about the theory behind why you need to make sure the stud is seated correctly and how you can ensure you’ve installed it right. You also get to see Cunningham use ARP’s new head stud installation tool that makes the entire process much easier.

These are just two of the many tips that are discussed in this video from Engine Pro. If you’re getting ready to put an engine together yourself this is a great resource to check out to ensure you install your head studs correctly the first time.