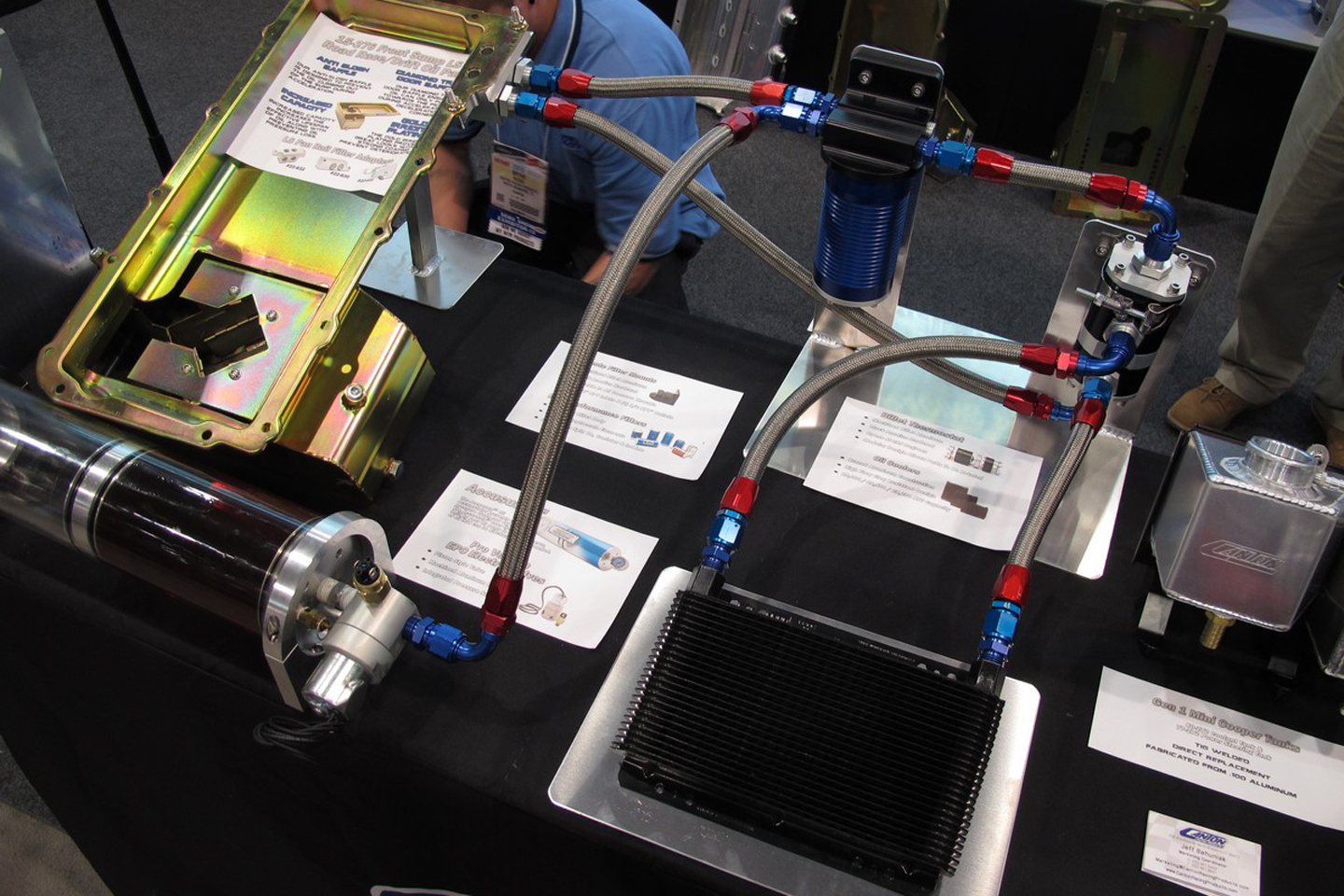

ARP Bolts have long been considered the “must-have” fasteners when it come to critical engine components, but their fastener technology extends well beyond engines. For example, ARP’s new Midget and Sprint Car U-Joint drive bolts are designed specifically to exceed the needs of the direct-drive open wheel dirt racecars.

In years past, car fabricators looked for hose ends and fasteners made for the aviation industry. As our friends at ARP have pointed out several times through the years, the terms “Aerospace Material” and “Aerospace Quality” have become buzz words implying the very best in design, materials and quality control. In racing, “aerospace” is not even close to good enough.

There are a number of important elements in the production of specialty fasteners, not the least of which are materials, design and manufacturing. ARP takes extraordinary steps to produce their products, and are considered by most car builders as the elite fasteners of their kind on the market today.

The company owners claim the key to their success in all areas is personnel. This is where ARP’s cadre of highly qualified and dedicated specialists shines the brightest.

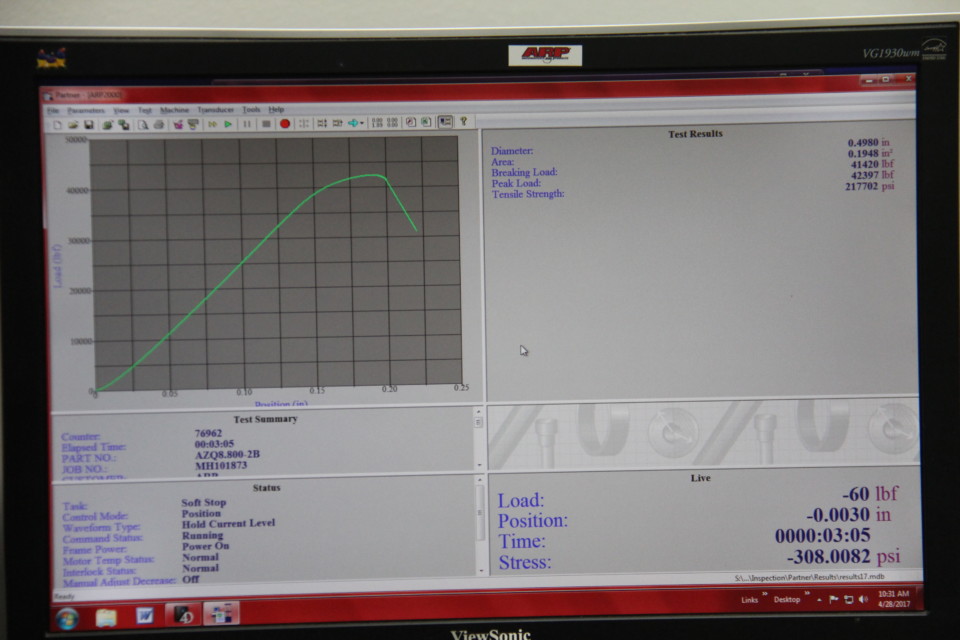

In order to ensure optimum quality control, ARP has grown to be self-reliant and controls all aspects of the manufacturing process. All operations are performed in-house and closely monitored. This is how ARP has been able to establish a reputation for “zero defect” quality throughout the industry.

For more information on ARP, their range of fasteners, or many of their technical articles, visit them online at arp-bolts.com.